Process heat

Indispensable in the manufacturing of numerous products

Particularly in industrial applications such as mechanical engineering, plant engineering and device manufacturing, optimal functionality, efficiency and a high durability are required to meet demands such as availability, competitiveness and efficiency.

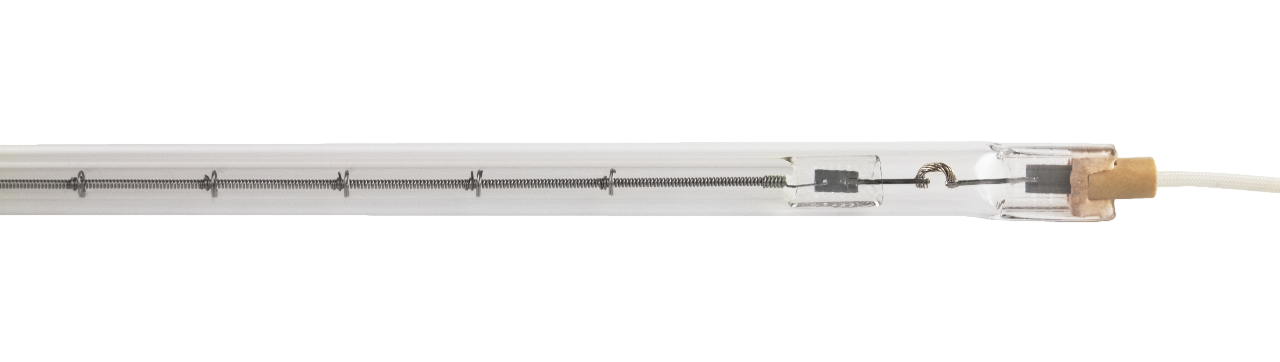

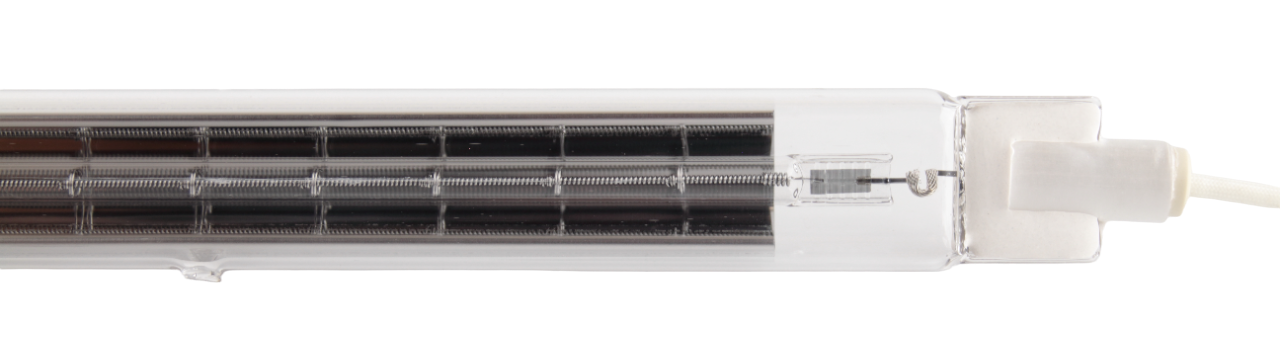

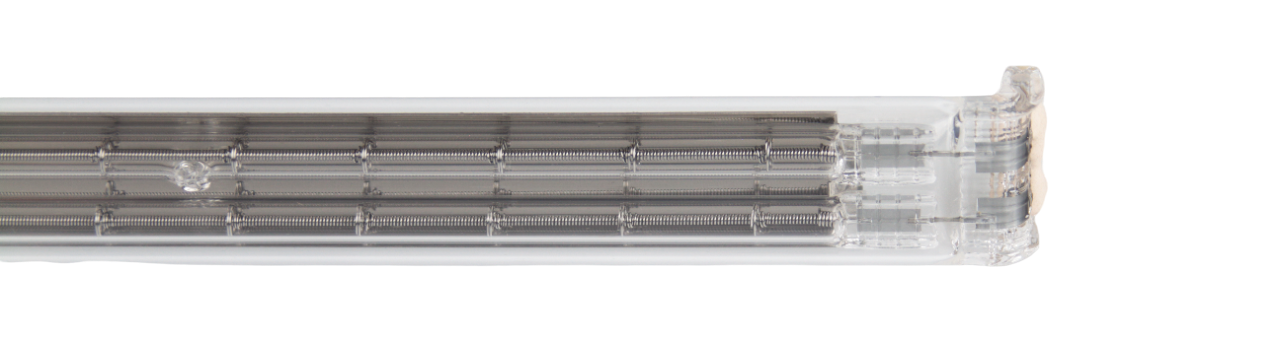

Depending on the heating task, different requirements are placed on the infrared heater.

The product defines the requirements

- Geometry and dimension of the material to be heated

- Material properties

- Operating environment and the available space

- Desired cycle times

Our infrared heaters offer the following advantages

- Fast, targeted heat

- Adapted to the specific heat task

- Energy-efficient, economical

- High durability

Industrial use of infrared radiation

Plastics

Depending on the material properties, the right wavelength must be used, particularly based on the absorption properties of the plastic to be heated. Other important criteria are the geometric and power-specific dimensioning of the infrared heater.Proper design ensures functionality and time savings, thus increasing productivity.

Since infrared heat is transferred to the plastic to be heated without contact and through the conversion of electrical energy into radiant energy, during which no gas emissions are released, the use of infrared heaters is also ideally for food packaging.

Application examples:

Blowing or deep drawing plastic container

Bending or deburring plastic sheets

Smoothing or shrinking plastic films

Laminating plastic films

Welding plastic rivets/tubes or membranes

Shrinking heat shrink tubes

Paper, -printing

In the industrial production of paper, cellulose and a significant amount of water are required. The dewatering necessary in the production process can be accelerated with infrared heaters.

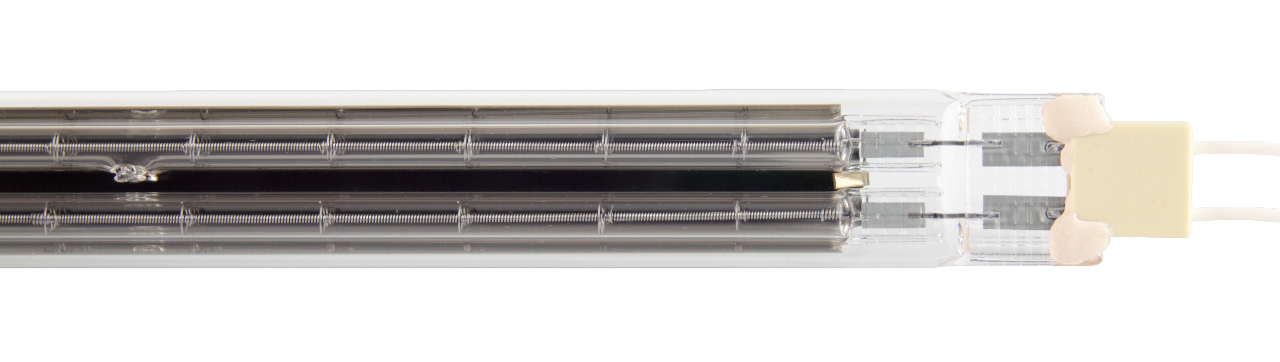

A similar heating task arises when drying water-based inks on paper. In order to achieve high efficiency of the electrical energy used, the emission from the infrared heater must be matched to the thermal properties of the water. Our fast medium-wave infrared heaters (type FQSM, QSM) with response times of approx. 3 seconds are specially designed for this heating task.

Application examples:

Accelerate dewatering

Drying inks

Burning-in toner

3D - Printing

In additive manufacturing using 3D printing of metallic or ceramic material, as found in dentistry, for example, subsequent sintering is necessary. An oven equipped with our durable, specially adapted infrared heaters (Typ HZR) guarantees to fulfill this heating task cleanly and reliably.

Application examples:

Sintering ceramics

Sintering metals

Electronics, photovoltaics

Infrared heaters are used, for example, to preheat circuit boards to prepare them for lead-free soldering. The adjustable infrared heaters quickly reach the desired temperature and are therefore ideally suited for intermittent operation. The heat is transferred without contact and quickly and evenly preheats the circuit boards.

Individual electronic components can also be heated using pin-base heaters (type SHS) or our airflow heater (type LSH), which can also be operated with inert or noble gases.

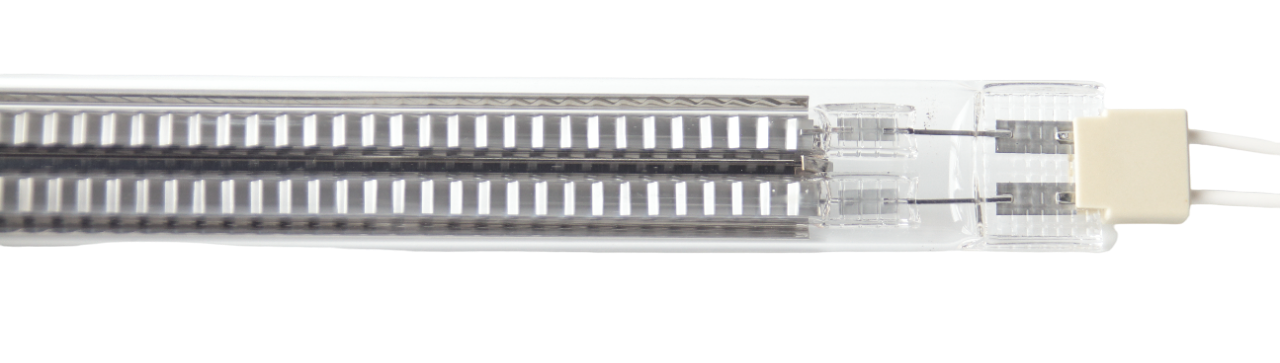

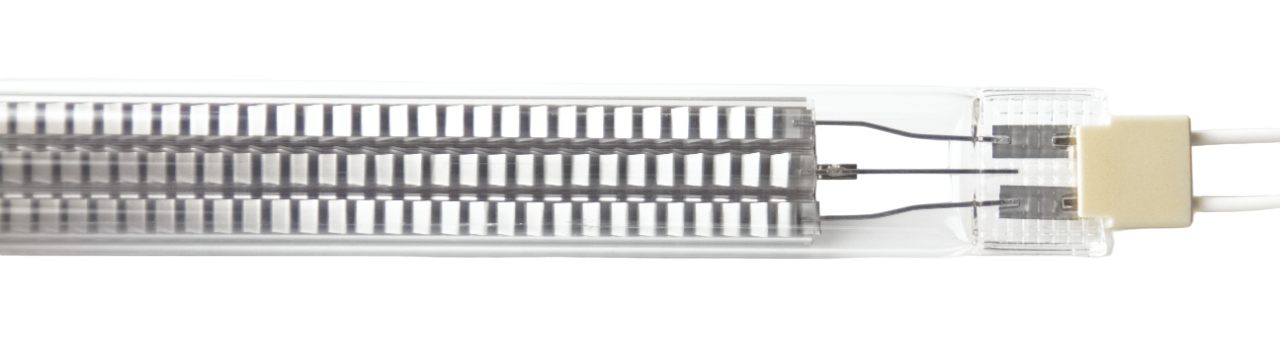

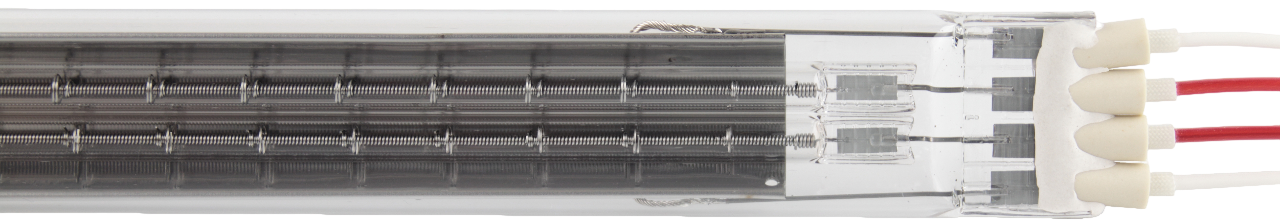

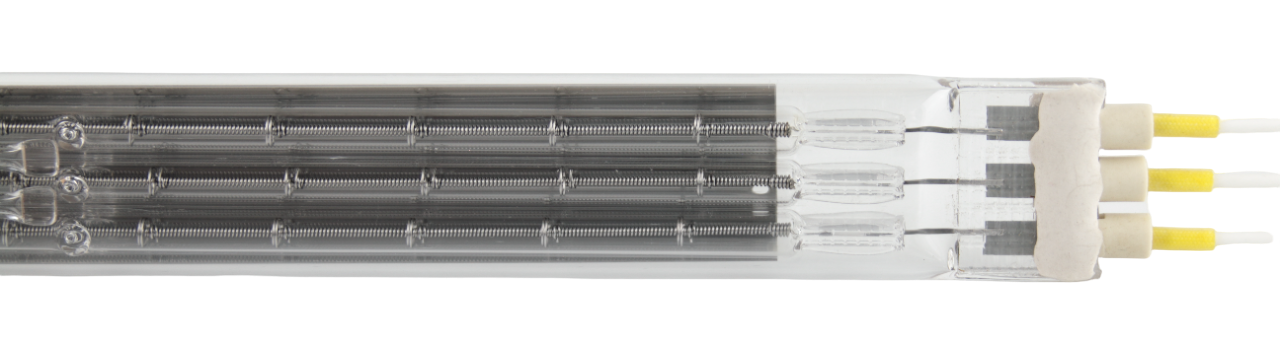

For heat applications in clean rooms, such as required in wafer production or photovoltaics, we recommend our infrared heaters in the multi-chamber system with an integrated reflector (type FQHS).

Application examples:

Preheating circuit boards

Preheating electronic components

Heating wafers

Solar technology

Automotive

In the automotive industry, infrared heaters are used for various heating processes. Some examples can be found in the tyre production, paint drying, interior trim production or laminated glass production. For rough industrial use, such as in tyre production, we recommend our external housing ( Protector heater), which protects the infrared heater from external influences.

Application examples:

Drying paint

Warming up tyres

Shaping interior trim

Connecting and tempering glass layers

Textile, -printing

Natural fibres and especially synthetic fibres only obtain the desired properties for later use through the right heat treatment. Depending on the heat requirement and the material properties of the textile, a wide variety of infrared heaters are used for this purpose.

Likewise, images, texts or graphics printed on textiles can be permanently burnt in using infrared radiation. The properties of the materials used are also essential for selecting the most suitable infrared heater for this purpose.

Application examples:

Melting synthetic fibres

Burning in textile dyes

Chemistry

Infrared heaters are used, for example, for drying and possibly curing adhesives. Depending on the composition of the adhesive, the drying time can be accelerated by adding heat. In general, chemical processes can be accelerated by adding heat.

As immersion heaters in liquids, we particularly recommend the infrared heaters that are configured as a multi-chamber system because of the thermal decoupling. Since the outer shell of our infrared heaters is made of pure quartz glass and is resistant to acidic and alkaline substances (except hydrofluoric acid and phosphoric acid), the infrared heaters in the multi-chamber system in particular can also be used in critical environmental conditions, if required with protected integrated reflector.

Application examples:

Curing adhesives

Accelerating chemical processes

Wood, -coating

Infrared heaters are ideal for drying glue, paints, lacquers or varnishes. Depending on the material used, the geometry and the desired cycle times or band speeds, various types of infrared heating elements are used. Especially for edge heating of coated chip boards we recommend our flat quartz bright heater with integrated parabolic reflector in a multi-chamber system (type FQHS-P).

Application examples:

Laminating edges, surfaces

Drying, curing paints, lacquers, varnishes

Medical technology

Due to the contactless heat transfer and the gas emission-free operation of the infrared heaters, it is possible to use them in medical technologies such as in clean rooms, for the production or packaging of medications. The hermetically sealed multi-chamber system and integrated reflector make it easy to clean and disinfect the infrared heater (type FQHS).

Application examples:

Sintering dental prostheses

Hyperthermia

Packaging of medication

Food

Infrared heating elements are suitable for baking, grilling, keeping warm, drying or roasting food. Especially the short-wave infrared radiation is ideal for the food industry due to its contactless heat transfer over longer distances. The integrated reflector makes cleaning the infrared heater (Typ FQHS) quick and easy. The use of infrared heaters in the food industry is a clean, safe and compact solution.

Application examples:

Melting cheese

Grilling meat or meat substitutes

Keeping food warm

Drying fruit

Drying vegetables

Roasting nuts