Overview IR emitters used for heating and drying processes

in plant engineering, mechanical engineering, equipment manufacturing and for industrial applications.

We develop, produce and distribute electrically operated infrared heating elements in various dimensions, geometries and shapes. Individual customer requests are welcome

We are also happy to use our 60 years of experience and know-how in dealing with infrared radiation to implement or optimise your heating or drying process.

Our constant goal is the success of our customers. Innovation and product quality in connection with economic efficiency are in the foreground.

We achieve resource savings by, among other things, maximising the efficiency and high durability of our products.

We will be happy to assist you in selecting the most suitable IR-heater for your heating task. Please do not hesitate to contact us.

Discover our diverse product portfolio.

Depending on the type of material to be heated, the optimal wavelength is required to achieve a high degree of efficiency. For this reason, we offer IR-heaters with different emission maxima and different dimensions, geometries and shapes in our product portfolio. Their wavelength ranges from 1.0 µm to 5.0 µm. (NIR-MIR)

- Optimum wavelength

- Different emission maxima

- Different dimensions, geometries and shapes

- Wavelength range from 1.0 µm to 5.0 µm. (NIR-MIR)

Short-wave and fast medium-wave IR heaters

Advantages

- High durability

- Very short response time of approx. 1 second

- High efficiency due to adjustment of the emission maximum

- High efficiency by adjusting the direction of emission

- Hermetically sealed multi-chamber system

- Increased safety due to the multi-chamber system

- Directed IR radiation due to integrated reflector

- Integrated reflector in its own protective gas medium

- Integrated reflector that cannot be negatively influenced from the outside

- Contactless heat transfer

- Can be used in a vacuum

- Suitable for clean rooms

- Infinitely variable 0-100%

- Gas emission-free

- Resistant to acidic and basic substances (except hydrofluoric and phosphoric acid)

- Very low thermal expansion

- High thermal shock resistance

Options

- With integrated reflector for directional or non-directional radiation

- Directional radiation as strip radiator, area radiator or high-intensity area radiator

- Heating length, energy density, emission maximum according to customer requirements

- Customised assembly of lead ends and contacts

- Lead on one or both sides

- Switchable heating zones

- Angled outer fusion

- Ceramic end

- Bending protection sleeve

- Grab handle

- Damping stop

- Radiation filter in the visible light range

Technology

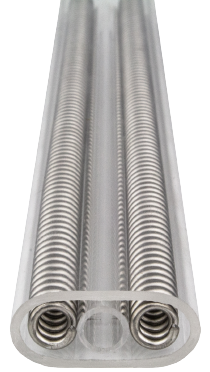

The IR radiator module consists of one or more inner IR-radiators, the IR-radiation emitters, an inner metallic reflector and an outer quartz cladding tube. We refer to this as a multi-chamber system.

The IR inner-radiator consists of a heating coil made of high temperature resistant metals, the most suitable atmosphere for this purpose and quartz glass as a protective cover. This heating coil or heating tape is heated by electrical energy and emits radiation in the infrared range with emission maxima of 1.0 μm to 2.8μm. The efficiency of the conversion of electrical energy to IR radiation energy is up to 90%.

The secondary chamber contains one or more internal IR emitters which, together with the optional reflector, is fused into an outer shell of quartz glass. This secondary chamber also contains the most suitable special atmosphere for this.

The purity of the materials used, high vacuum technology and the choice of the most suitable atmospheres in the respective chambers, combined with the multi-chamber system, enable us to achieve the exceptionally durability. The results are reliability, saving of resources and costs for maintenance.

The individual adjustment of the heating length, the heating power and the emission maximum to the material to be heated saves energy and time.

With the help of a specially shaped, integrated reflector, the emitted IR-radiation hits the spot where it is needed.

The short-wave IR-radiator takes approx. 1 second to reach its operating state. If the IR- heater is only operated when heat is needed, high savings of electrical energy are guaranteed.

Due to the possible infinitely variable control from 0-100%, the emission maximum and the power of the IR radiant heater can be optimally adjusted to the heating task, if required.

For materials of different sizes to be heated, the heating zone required at the time can be freely selected, if possible, by means of switchable heating zones with an IR radiant heater.

With possible power densities of up to 150W/cm, related to the heating zone of the IR radiant heater, the highest energy density is generated in the smallest space. We offer radiant heater lengths of up to 2 metres in various designs.

By converting electrical energy into IR- radiation energy, IR-heaters are emission-free. The emitted IR radiation energy is transferred to the material to be heated without contact and converted into heat by absorption directly in the material to be heated.

The hermetically sealed multi-chamber system ensures that the integrated reflector and the Infrared heating elements are protected from external influences such as dust or scratches.

This also makes the IR radiation module ideally suited for cleanrooms.

continue to the products for this IR radiant heater

Medium-wave IR-heaters

Advantages

- High durability

- Response time 0.1 - 2 minutes

- High efficiency due to adjustment of emission maximum

- Infinitely variable 0-100%

- Emission-free

- Contactless heat transfer

- Very low thermal expansion

- High thermal shock resistance

Options

- Heating length, energy density, emission maximum according to customer requirements

- Geometry or shape according to customer requirements

- Customised assembly of lead ends and contacts

- Lead on one or both sides

- Switchable heating zones

- Directional or non-directional radiation

Technology

The medium-wave IR radiant heater consists of one or multiple heating coils, the Infrared heating elements and an outer quartz cladding tube.

This heating coil is heated by means of electrical energy and emits radiation in the infrared range with emission maxima of 2.2 μm to 5.0 μm.

By properly dimensioning the heating coil, using high-purity materials and treating them appropriately, we achieve a long service life. The results are reliability, saving of resources and costs for maintenance.

The individual adaptation of the heating length, the heating power, the emission maximum and the geometry to the material to be heated saves energy.

With the help of an attached gold reflector, the emitted IR-radiation hits the spot where it is needed. Alternatively, a specially shaped external reflector can be used.

The switch-on time of the medium-wave IR radiant heater depends on its design and ranges from 0.1 to 2 minutes to reach the operating state. If the IR radiant heater is only operated when heat is needed, high savings in electrical energy are guaranteed.

Due to the possible infinitely variable control from 0-100%, the emission maximum and the power of the IR radiant heater can be optimally adjusted to the heating task.

For materials of different sizes to be heated, the heating zone required at the time can be freely selected by means of switchable heating zones with an IR-heater.

With possible power densities of up to 80W/cm, related to the heating zone of the IR radiant heater, the highest energy density is generated in the smallest space. We offer radiant heater lengths of up to 2 metres in various designs.

By converting electrical energy into IR radiation energy, IR-heaters are free of emissions. The emitted IR radiant energy is transferred to the material to be heated without contact and converted into heat by absorption directly in the material to be heated.