Medium-wave Infrared heating elements

Design and properties

Overview

| Description | Radiation1 | Number of heating coils | quartz cross-section2 | Lead ends | Core diameter2 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Product details FQS |

Quartz flat tube | non-directional | 2 | 21x10, 29x13 | One-sided | ||||

| Product details QS |

Quartz round tube | non-directional | 1 | ø8, ø10, ø13 | Both-sided | ||||

|

Product details HZR |

Hollow cylinder | non-directional | 1 | ø8, ø10, ø13 | Both-sided | ø70 – ø150 | |||

| Product details RQS |

Quartz ring | non-directional | 1 | ø8, ø10, ø13 | Both-sided | ø50 – ø800 | |||

| Product details HSR |

Half-shell | directional | 2 | 2x ø8 | One-sided | ø12, ø25, ø51, ø76 |

| Description | Voltage and power | Number of heating coils | quartz cross-section1 | length quartz tube1 | Lead ends | ||||

|---|---|---|---|---|---|---|---|---|---|

| Product details LSH |

Standard | 230V-500W | 1 | ø 16 | 128 | One-sided |

type: FQS / Quartz flat tube infrared heating element

The FQS is an IR-heating element consisting of two or more heating coils as Infrared heating elements located in an outer quartz flat tube.

The FQS is suitable for heating a surface, a room or a band. Due to the optional gold reflector, the IR radiation is directed and hits where it is needed for heating.

The use in ambient temperatures of up to 1000°C, as required e.g. in the oven construction, is possible without any problems if the unit is adapted accordingly.

The switch-on time of the FQS can be from 0.1 to 2 minutes to reach the operating state.

The following are eligible

- Heating length up to 2 metres

- Heating power in combination with the supply voltage

- Emission maximum of the emitted IR radiation between 2,2 μm – 5,0 μm

- Energy density in relation to the heating length up to 80W/cm

We have a wide range of standard products. We will be happy to assist you in selecting the most suitable IR radiant heater for your heating task. Please do not hesitate to contact us.

The following table shows the standard FQS types in different versions. They differ in the number of heating coils, the radiation and the quartz cross-section.

Advantages

- High durability

- Response time 0,1 – 2 minutes

- High efficiency through adjustment of the emission maximum

- Infinitely variable 0-100%

- Emission-free

- Contactless heat transfer

- Very low heat expansion

- High thermal shock resistance

- No increased inrush current

Options

- Heating length, energy density, emission maximum

- Lead ends on both sides (Z)

- Switchable heating zones

- Gold reflector (G)

- Customised assembly of the lead ends and contacts

- External quartz fusion up to 1000°C operating temperature (E)

Type FQS

Type FQS-G

Options

| Type | Description | Radiation1 | Number of heating coils | Quartz cross-section Angabe2 | Lead ends | gold reflector |

|---|---|---|---|---|---|---|

| FQS | Standard | Radiant heater | 2 | 21x10, 29x13 | One-sided | |

| FQS-G | Reflektor | Surface radiator | 2 | 21x10, 29x13 | One-sided | x |

| FQS-Z | Switchable | Radiant heater | 2 | 21x10, 29x13 | Both-sided | |

| FQS-3Y | Parabolic triple | Radiant heater intensive | 3 | 29x13, 33x15 | One-sided |

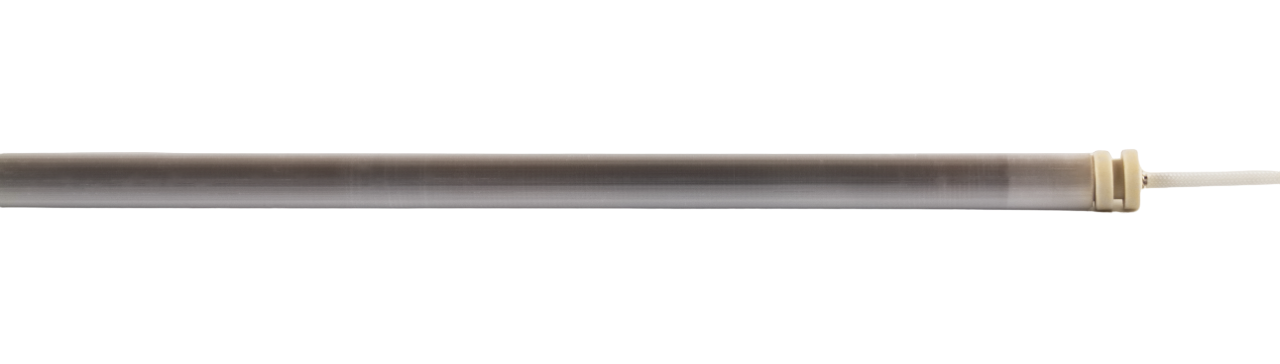

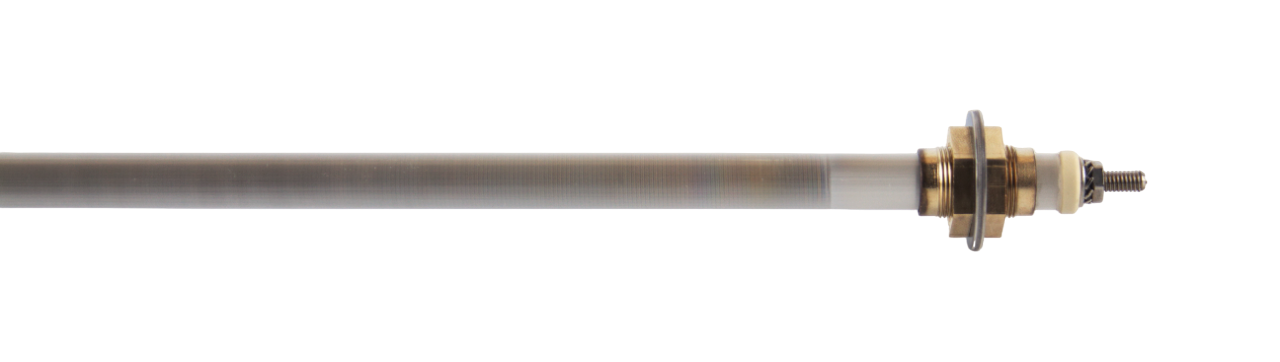

type: QS / Quartz-round tube infrared heating element

The QS is an IR radiant heater consisting of a heating coil as an IR-emitter located in an outer quartz round tube.

The QS is suitable for heating a surface, a room or a band. Due to the optional gold reflector, the IR radiation is directed and hits where it is needed for heating.

The use in ambient temperatures of up to 1000°C, as required e.g. in oven construction, is possible without any problems if the unit is adapted accordingly.

The switch-on time of the QS can be from 0.1 to 2 minutes to reach the operating state.

The following are eligible

- Heating length up to 2 metres

- Heating power in combination with the supply voltage

- Emission maximum of the emitted IR radiation between 2,2 μm – 5,0 μm

- Energy density in relation to the heating length up to 50W/cm

We have a wide range of standard products. We will be happy to assist you in selecting the most suitable IR radiant heater for your heating task. Please do not hesitate to contact us.

The following table shows the standard types QS in different versions. They differ in the quartz cross-section.

Advantages

- High durability

- Response time 0,1 – 2 minutes

- High efficiency through adjustment of the emission maximum

- Infinitely variable 0-100%

- Emission-free

- Contactless heat transfer

- Very low heat expansion

- High thermal shock resistance

- No increased inrush current

Options

- Heating length, energy density, emission maximum

- Gold reflector (G)

- External quartz fusion up to 1000°C operating temperature (E)

- Customised assembly of the lead ends and contacts

- Fixation by means of threaded sleeve (GH)

Type QS

Type QS-GH

Options

| Type | Description | Radiation1 | Number of heating coils | Quartz cross-section2 | Lead ends |

|---|---|---|---|---|---|

| QS | Standard | Radiant heater | 1 | ø8, ø10, ø13 | Both-sided |

| QS-GH | Gewindehülse | Radiant heater | 1 | ø10, ø13 | Both-sided |

type: HZR / Quartz-hollow cylinder infrared heating element

The HZR is an IR heating element consisting of a heating coil as an IR radiation emitter, which is located in an outer quartz round tube formed into a hollow cylinder.

The HZR is suitable for heating a room.

Use in ambient temperatures of up to 1000°C, as required in furnace construction, for example, is possible without any problems if the unit is adapted accordingly.

The switch-on time of the HZR can be from 0.1 to 2 minutes to reach the operating state.

The following are eligible

- Der Core diameter 70 – 150mm and the height of the quartz tube cylinder

- Heating power in combination with the supply voltage

- Emission maximum of the emitted IR radiation between 2,2 μm – 5,0 μm

- Energy density in relation to the heating length up to 50W/cm

We have a wide range of standard products. We will be happy to assist you in selecting the most suitable IR radiant heater for your heating task. Please do not hesitate to contact us.

The following table shows the standard types HZR in different versions. They differ in the core diameter, the quartz cross-section and the height of the hollow cylinder.

Advantages

- High durability

- Response time 0,1 – 2 minutes

- High efficiency through adjustment of the emission maximum

- Infinitely variable 0-100%

- Emission-free

- Contactless heat transfer

- Very low heat expansion

- High thermal shock resistance

- No increased inrush current

- External quartz fusion up to 1000°C operating temperature (E)

Options

- Energy density, emission maximum according to customer requirements

- Gold reflector (G)

- Heating power in combination with the supply voltage

- Core diameter, height of the hollow cylinder according to customer's requirements.

- Customised assembly of lead ends

Type HZR-6Wdg.

Type HZR-4Wdg.

| Type | Description | Radiation1 | Number of heating coils | Quartz cross-section2 | Core diameter2 | Lead ends |

|---|---|---|---|---|---|---|

| HZR | Standard | Radiant heater | 1 | ø8, ø10, ø13 | ø70 - ø150 | Both-sided |

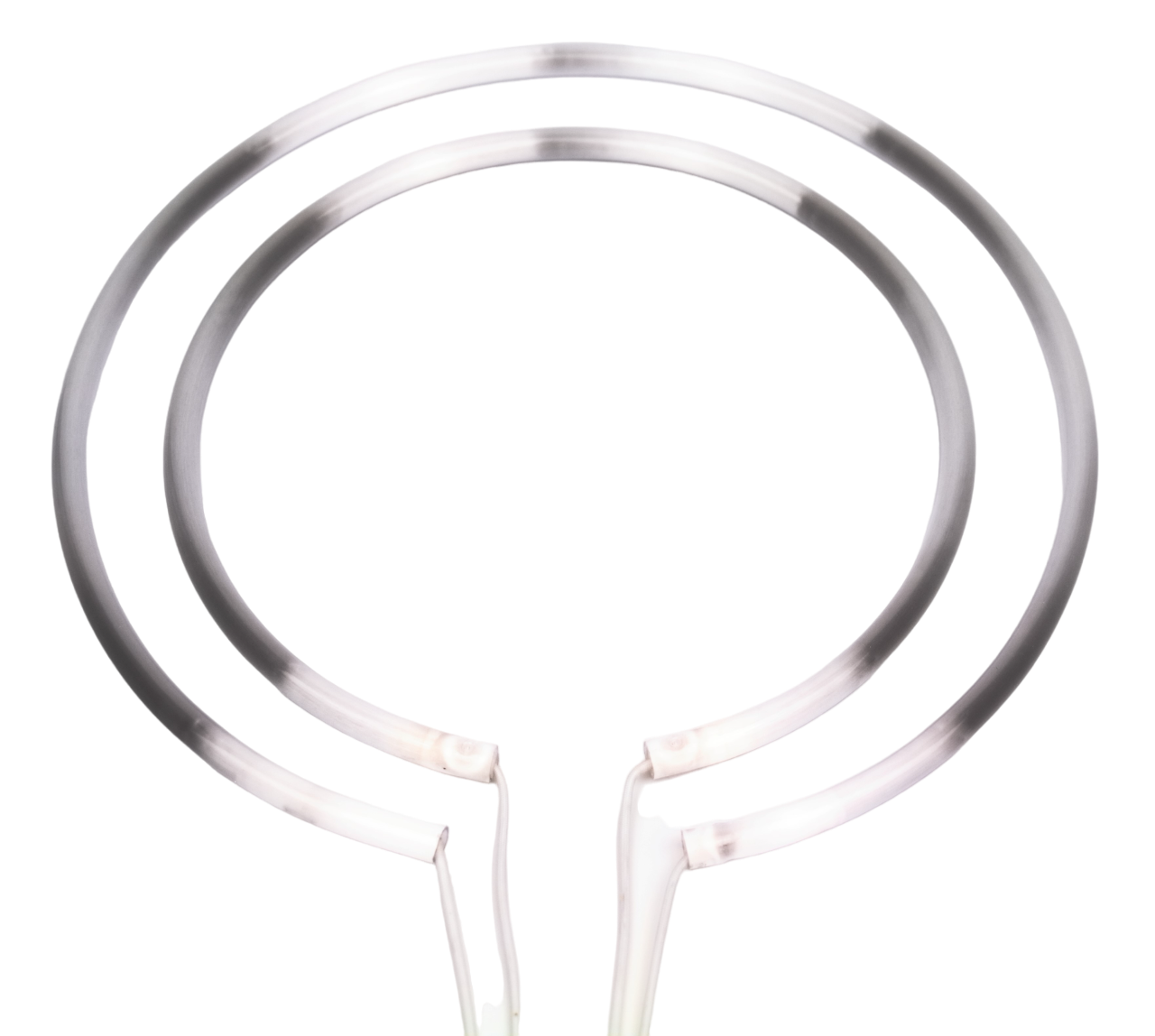

type: RQS / Quartz ring infrared heating element

The RQS is an IR radiant heater consisting of a heating coil as an IR radiation emitter, which is located in an outer quartz round tube formed into a ring.

The RQS is suitable for heating a room or a round surface, in combination with an external reflector as a heating plate.

The use in ambient temperatures of up to 1000°C, as required in oven construction, for example, is possible without any problems if the unit is adapted accordingly.

The switch-on time of the RQS can be from 0.1 to 2 minutes to reach the operating state.

The following are eligible

- Der Core diameter 50 – 800mm and the cross section of the quartz tube

- Heating power in combination with the supply voltage

- Emission maximum of the emitted IR radiation between 2,2 μm – 5,0 μm

- Energy density in relation to the heating length up to 50W/cm

We have a wide range of standard products. We will be happy to assist you in selecting the most suitable IR radiant heater for your heating task. Please do not hesitate to contact us.

The following table shows the standard type RQS in different versions. The differences lie in the core diameter and the quartz cross-section.

Advantages

- High durability

- Response time 0,1 – 2 minutes

- High efficiency through adjustment of the emission maximum

- Infinitely variable 0-100%

- Emission-free

- Contactless heat transfer

- Very low heat expansion

- High thermal shock resistance

- No increased inrush current

Options

- Energy density, emission maximum according to customer requirements

- Gold reflector (G)

- Heating power in combination with the supply voltage

- Core diameter according to customer request

- Customised assembly of lead ends

- External quartz fusion up to 1000°C operating temperature (E)

Type RQS

| Type | Description | Radiation1 | Number of heating coils | Quartz cross-section2 | Core diameter2 | Lead ends |

|---|---|---|---|---|---|---|

| RQS | Standard | Radiant heater | 1 | ø8, ø10, ø13 | ø50 – ø800 | Both-sided |

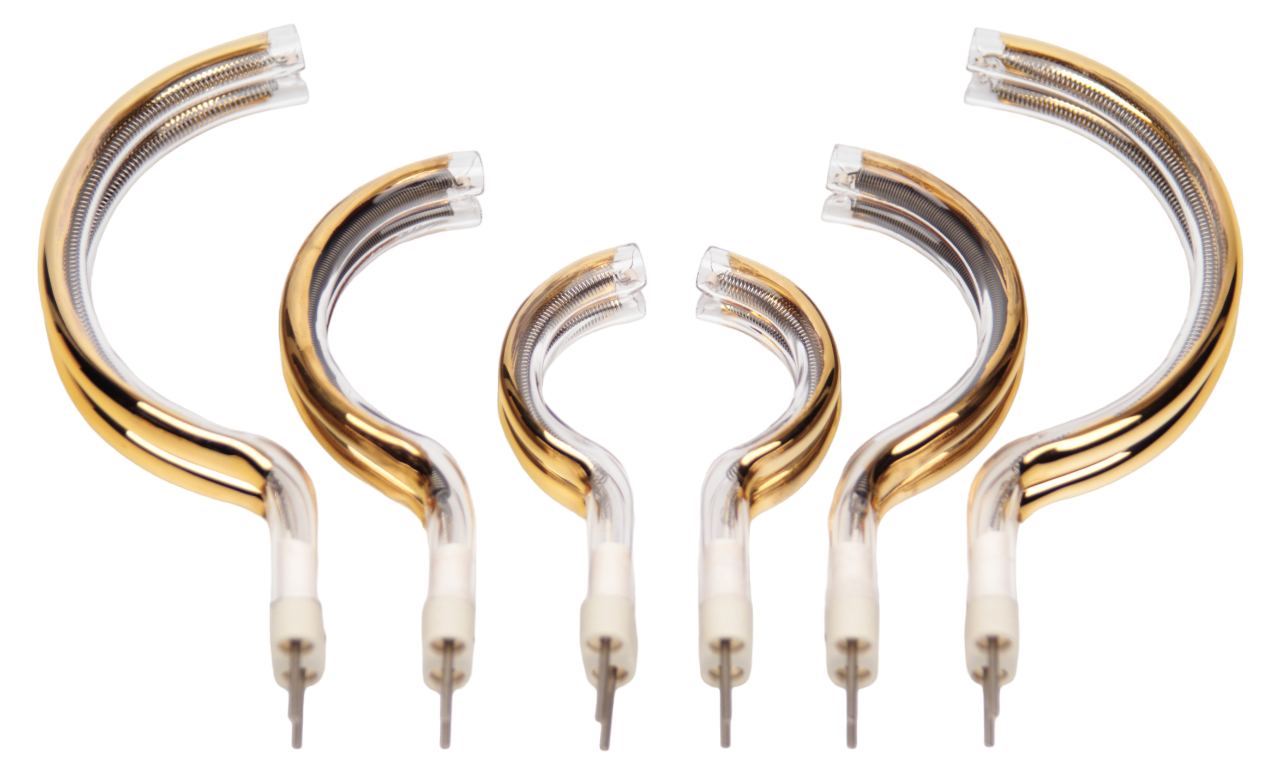

type: HSR / Quartz half-shell infrared heating element

The HSR is an IR radiant heater consisting of two heating coils as Infrared heating elements, which are located in an outer quartz double round tube formed into a half shell. The quartz double round tube is coated on the outside with a gold reflector on one side as standard. The base is designed with a ceramic end and plug-in contacts as standard.

The HSR is suitable for heating a cylinder. Examples of applications would be the shrinking of a heat-shrinkable tube, the melting of plastic rivets or the edge heating of a circular blank.

Use in ambient temperatures of up to 1000°C, as required in the oven construction, for example, is possible without any problems if the HSR is adapted accordingly.

The switch-on time of the HSR can be from 0.1 to 2 minutes to reach the operating state.

The standard core diameters are 12mm, 26mm, 51mm, 76mm.

The following are eligible

- Heating power in combination with the supply voltage

- Emission maximum of the emitted IR radiation between 2,2 μm – 5,0 μm

- Energy density in relation to the heating length up to 40W/cm

We have a wide range of standard products. We will be happy to assist you in selecting the most suitable IR radiant heater for your heating task. Please do not hesitate to contact us.

Advantages

- High durability

- Response time 0,1 – 0,5 minutes

- High efficiency through adjustment of the emission maximum

- Infinitely variable 0-100%

- Emission-free

- Contactless heat transfer

- Very low heat expansion

- High thermal shock resistance

- No increased inrush current

Options

- Energy density, emission maximum according to customer requirements

- Heating power in combination with the supply voltage

- Core diameter according to customer request

- Customised assembly of lead ends

- External quartz fusion up to 1000°C operating temperature (E)

Type HSR

| Type | Description | Radiation | Number of heating coils | Quartz cross-section1 | Core diameter1 | Lead end socket |

|---|---|---|---|---|---|---|

| HSR ½“ | Standard | Cylindrical to the inside | 2 | 2x ø8 | ø12 | One-sided |

| HSR 1“ | Standard | Cylindrical to the inside | 2 | 2x ø8 | ø26 | One-sided |

| HSR 2“ | Standard | Cylindrical to the inside | 2 | 2x ø8 | ø51 | One-sided |

| HSR 3“ | Standard | Cylindrical to the inside | 2 | 2x ø8 | ø77 | One-sided |

type: LSH / Airflow Heater

The LSH is a heating element consisting of a meander-shaped heating coil located in an outer quartz round tube. For the hose connection, this quartz round tube is provided with a rotary part on one side. The electrical connection is made on one side.

The LSH is suitable for heating a small area, such as is required for preheating small electronic components.

Non-flammable gases such as air, inert gases or noble gases can be used as heat transport medium. Heating takes place by means of convection, as is known from the hairdryer principle.

Depending on the gas flow rate, the HSR takes between 2 s and 10 s to reach the operating state.

The standard dimension of the quartz round tube is ø16 x 128mm

We have a wide range of standard products. We will be pleased to assist you in selecting the most suitable IR radiant heater for your heating task. Please do not hesitate to contact us.

The following table shows the standard type LSH.

Advantages

- High durability

- Response time 2 - 10 seconds

- Infinitely variable 0-100%

- Very low heat expansion

- High thermal shock resistance

- No increased inrush current

Options

- Geometric dimensioning according to customer requirements

- Heating power in combination with the supply voltage

- Customised assembly of lead ends

Type LSH

| Type | Description | Voltage and power | Number of heating coils | Quartz cross-section1 | length quartz tube1 | Lead ends |

|---|---|---|---|---|---|---|

| LSH | Standard | 230V-500W | 1 | ø 16 | 128 | One-sided |