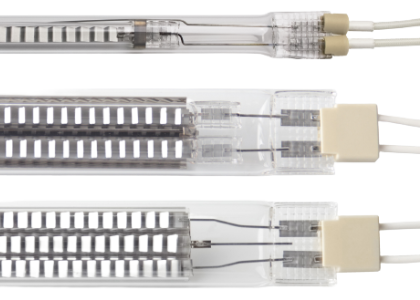

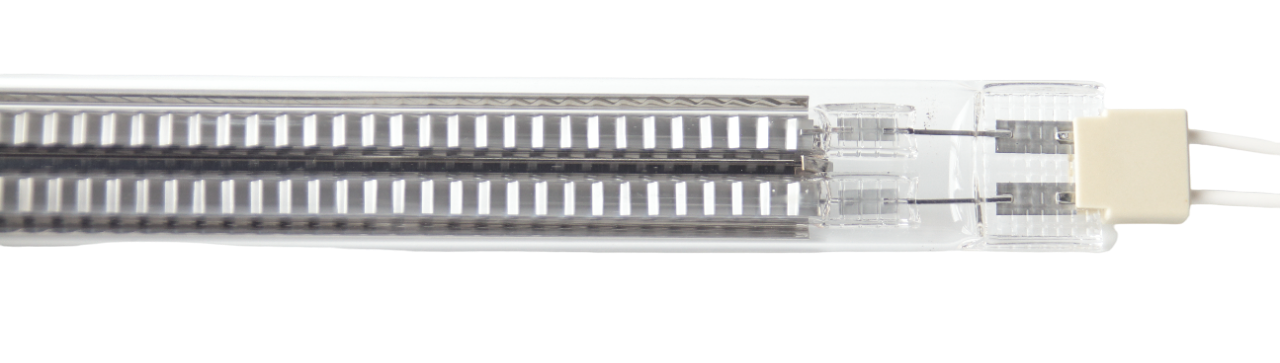

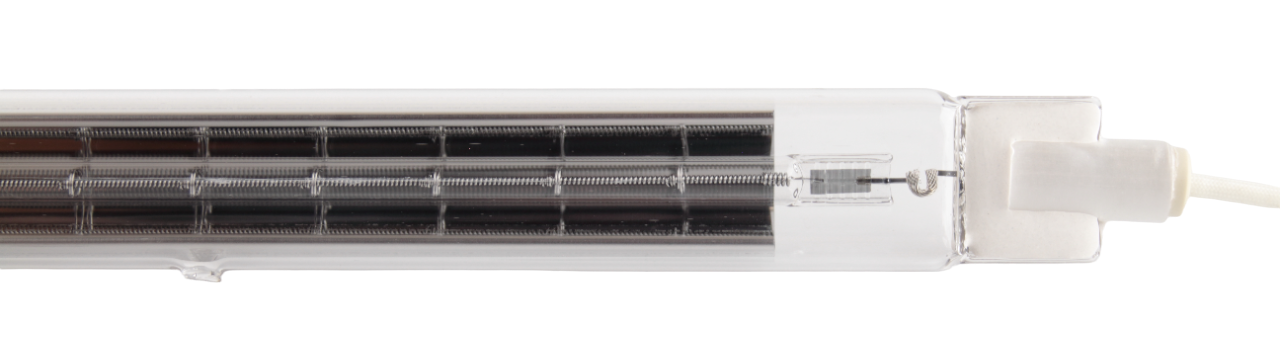

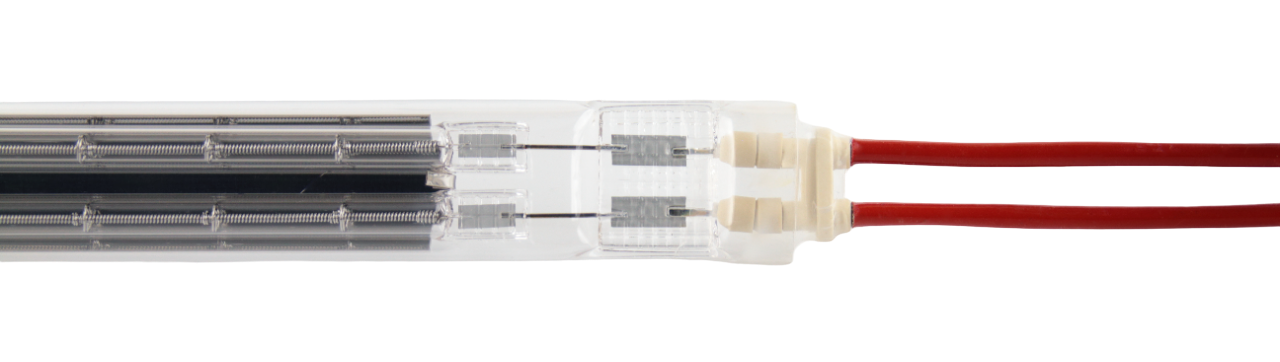

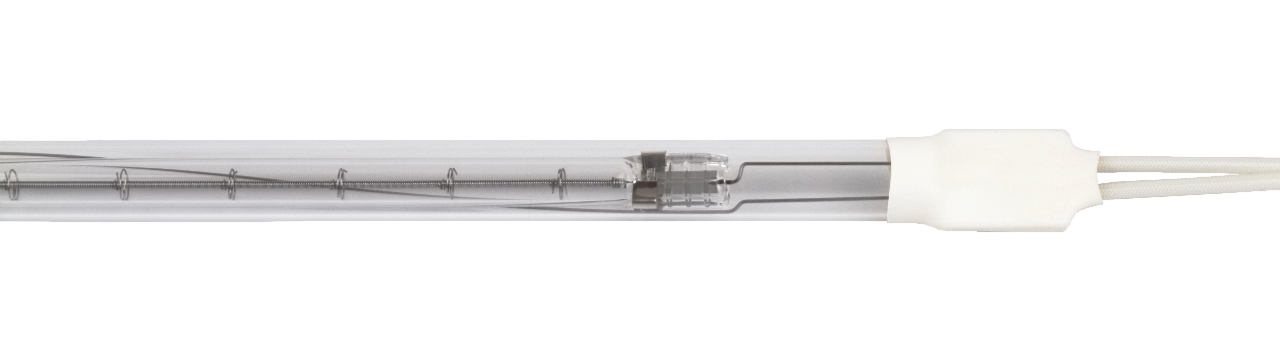

type: FQSM / Quartz flat tube- fast medium wave with integrated reflector and one-sided lead end in multi-chamber system

The FQSM is an IR -heating element consisting of one or more primary radiators as Infrared heating elements, which together with an integrated reflector is located in a hermetically sealed outer quartz flat tube, the secondary chamber. Each chamber is filled with the atmosphere best suited to it.

The FQSM is particularly suitable for heating a surface or a band. Due to the integrated reflector, the IR radiation is already directed and hits where it is needed for heating. The external melting must not exceed 350°C in operation under normal atmosphere. Use in a vacuum is also possible without any problems.

The switch-on time of the FQSM is approx. 3 seconds to reach the operating state.

The following are eligible

- Heating length up to 2 metres

- Heating power in combination with the supply voltage

- Emission maximum of the emitted IR radiation between 1,8 μm - 2,8 μm.

- Energy density in relation to the heating length up to 50 W/cm.

We have a wide range of standard products. We are happy to assist you in selecting the most suitable IR heater for your heating task. Please do not hesitate to contact us.

The following table shows the standard types of FQSM in different versions. They differ in the number of primary radiators.

Advantages

- Multi-chamber system hermetically sealed to the outside

- Directed IR radiation through integrated reflector

- Integrated reflector in its own protective gas medium

- Integrated reflector that cannot be negatively influenced from the outside

- Increased safety due to the multi-chamber system

- High durability

- Kurze Ansprechzeit von ca. 3 Sekunden

- Infinitely variable 0-100%

- High efficiency through adjustment of the emission maximum

- Contactless heat transfer

- Can be used in vacuum

- Suitable for cleanroom

- Emission-free

- Resistant to acidic and basic substances (with the exception of hydrofluoric and phosphoric acid)

- Very low heat expansion

- High thermal shock resistance

Options

- Lead ends on both sides (Z)

- Switchable heating zones

- Customised assembly of the lead ends and contacts

- Angled outer fusion (90°)

- Ceramic end (K)

- Cable bend relief (T)

Type FQSM-2

Type FQSM-3

| Type | Description | Radiation | Radiation angle1 | Number of primary radiators | Flat quartz cross-section2 | Integrated reflector |

|---|---|---|---|---|---|---|

| FQSM-2 | Fast medium wave | Surface radiator | 120 | 2 | 29x13 | x |

| FQSM-3 | Fast medium wave | Surface radiator | 120 | 3 | 29x13 | x |

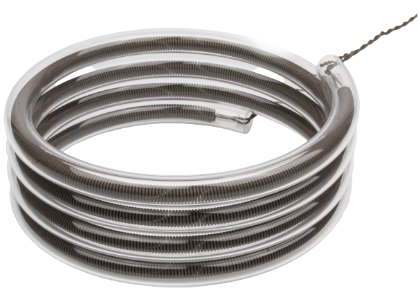

type: HZR / Quartz-hollow cylinder infrared heating element

The HZR is an IR heating element consisting of a heating coil as an IR radiation emitter, which is located in an outer quartz round tube formed into a hollow cylinder.

The HZR is suitable for heating a room.

Use in ambient temperatures of up to 1000°C, as required in furnace construction, for example, is possible without any problems if the unit is adapted accordingly.

The switch-on time of the HZR can be from 0.1 to 2 minutes to reach the operating state.

The following are eligible

- Der Core diameter 70 – 150mm and the height of the quartz tube cylinder

- Heating power in combination with the supply voltage

- Emission maximum of the emitted IR radiation between 2,2 μm – 5,0 μm

- Energy density in relation to the heating length up to 50W/cm

We have a wide range of standard products. We will be happy to assist you in selecting the most suitable IR radiant heater for your heating task. Please do not hesitate to contact us.

The following table shows the standard types HZR in different versions. They differ in the core diameter, the quartz cross-section and the height of the hollow cylinder.

Advantages

- High durability

- Response time 0,1 – 2 minutes

- High efficiency through adjustment of the emission maximum

- Infinitely variable 0-100%

- Emission-free

- Contactless heat transfer

- Very low heat expansion

- High thermal shock resistance

- No increased inrush current

- External quartz fusion up to 1000°C operating temperature (E)

Options

- Energy density, emission maximum according to customer requirements

- Gold reflector (G)

- Heating power in combination with the supply voltage

- Core diameter, height of the hollow cylinder according to customer's requirements.

- Customised assembly of lead ends

Type HZR-6Wdg.

Type HZR-4Wdg.

| Type | Description | Radiation1 | Number of heating coils | Quartz cross-section2 | Core diameter2 | Lead ends |

|---|---|---|---|---|---|---|

| HZR | Standard | Radiant heater | 1 | ø8, ø10, ø13 | ø70 - ø150 | Both-sided |

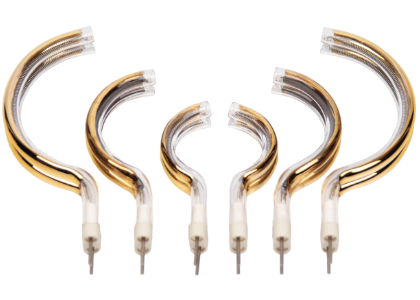

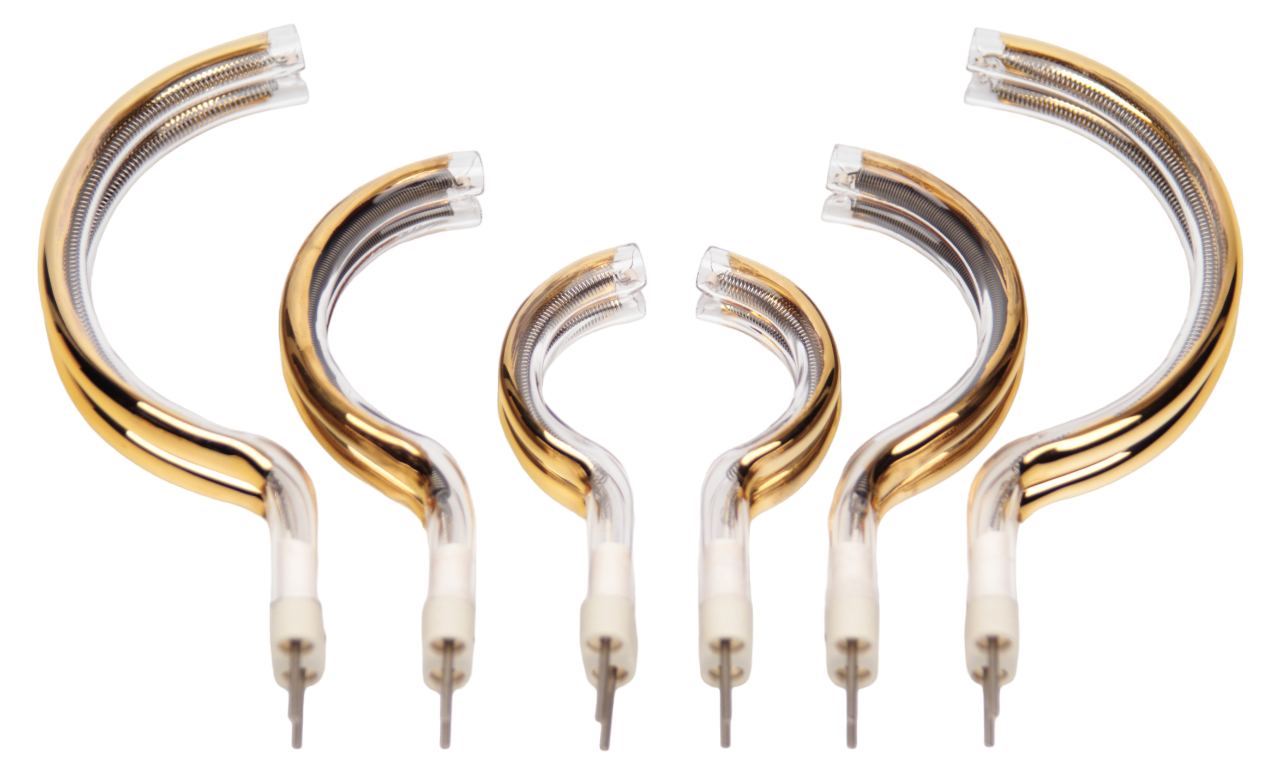

type: HSR / Quartz half-shell infrared heating element

The HSR is an IR radiant heater consisting of two heating coils as Infrared heating elements, which are located in an outer quartz double round tube formed into a half shell. The quartz double round tube is coated on the outside with a gold reflector on one side as standard. The base is designed with a ceramic end and plug-in contacts as standard.

The HSR is suitable for heating a cylinder. Examples of applications would be the shrinking of a heat-shrinkable tube, the melting of plastic rivets or the edge heating of a circular blank.

Use in ambient temperatures of up to 1000°C, as required in the oven construction, for example, is possible without any problems if the HSR is adapted accordingly.

The switch-on time of the HSR can be from 0.1 to 0.5 minutes to reach the operating state.

The standard core diameters are 12mm, 26mm, 51mm, 76mm.

The following are eligible

- Heating power in combination with the supply voltage

- Emission maximum of the emitted IR radiation between 2,2 μm – 5,0 μm

- Energy density in relation to the heating length up to 40W/cm

We have a wide range of standard products. We will be happy to assist you in selecting the most suitable IR radiant heater for your heating task. Please do not hesitate to contact us.

Advantages

- High durability

- Response time 0,1 – 0,5 minutes

- High efficiency through adjustment of the emission maximum

- Infinitely variable 0-100%

- Emission-free

- Contactless heat transfer

- Very low heat expansion

- High thermal shock resistance

- No increased inrush current

Options

- Energy density, emission maximum according to customer requirements

- Heating power in combination with the supply voltage

- Core diameter according to customer request

- Customised assembly of lead ends

- External quartz fusion up to 1000°C operating temperature (E)

Type HSR

| Type | Description | Radiation | Number of heating coils | Quartz cross-section1 | Core diameter1 | Lead end socket |

|---|---|---|---|---|---|---|

| HSR ½“ | Standard | Cylindrical to the inside | 2 | 2x ø8 | ø12 | One-sided |

| HSR 1“ | Standard | Cylindrical to the inside | 2 | 2x ø8 | ø26 | One-sided |

| HSR 2“ | Standard | Cylindrical to the inside | 2 | 2x ø8 | ø51 | One-sided |

| HSR 3“ | Standard | Cylindrical to the inside | 2 | 2x ø8 | ø77 | One-sided |

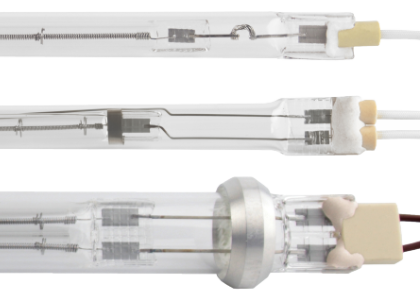

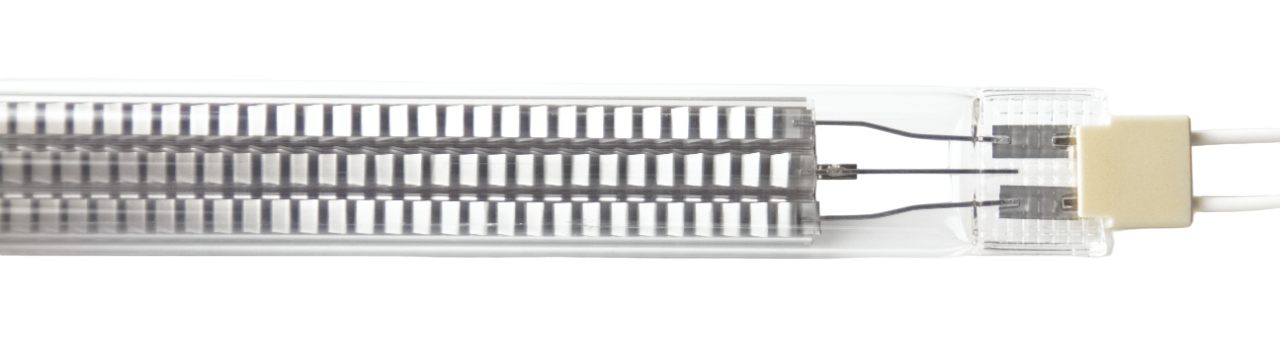

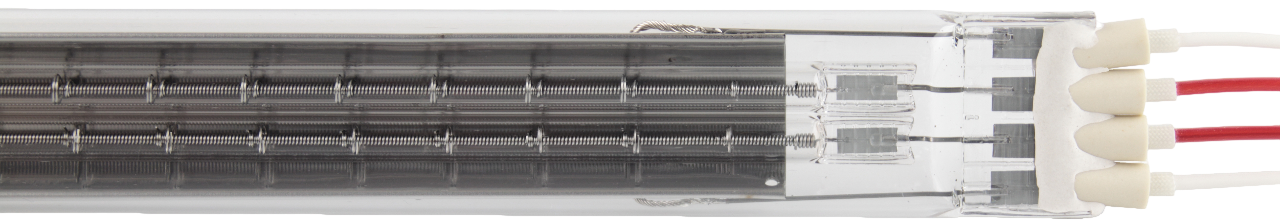

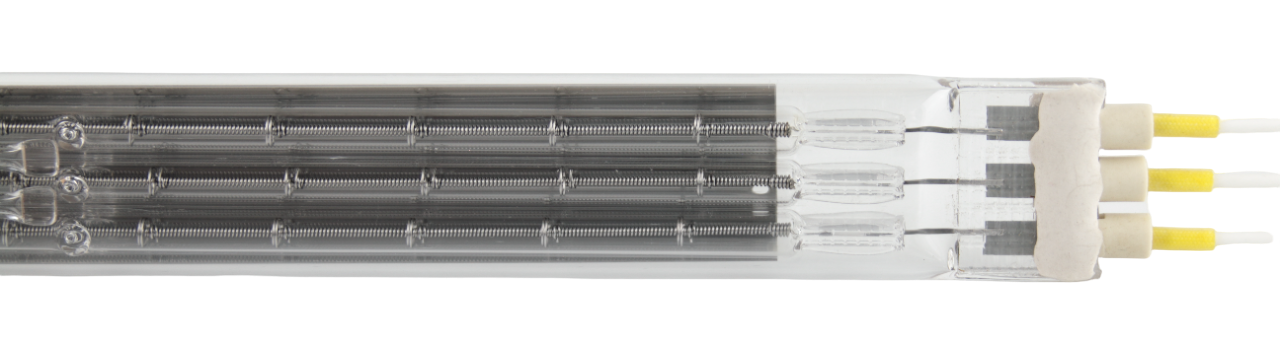

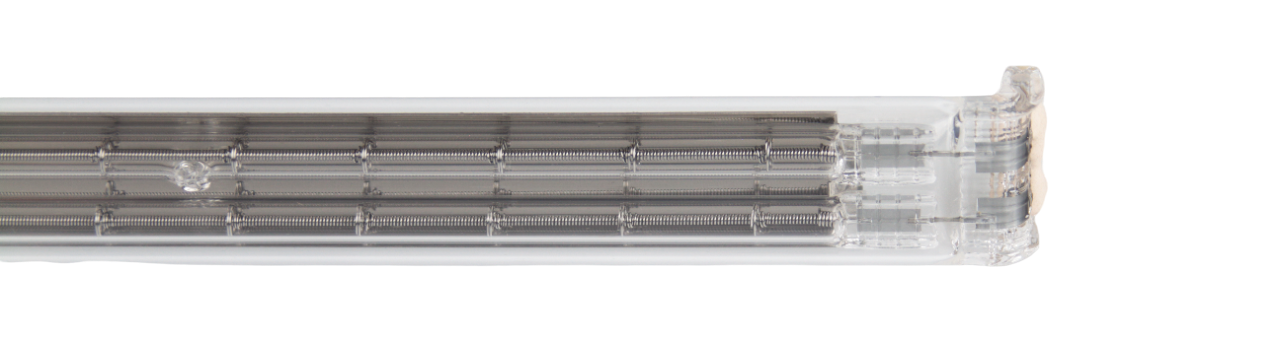

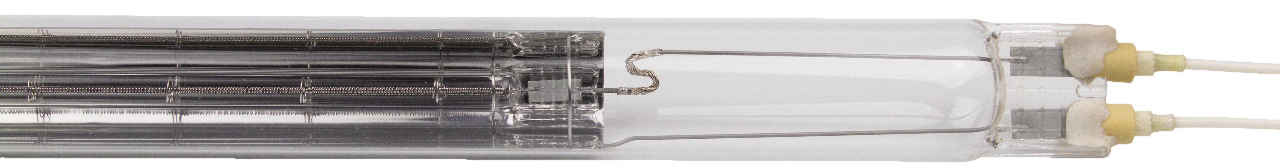

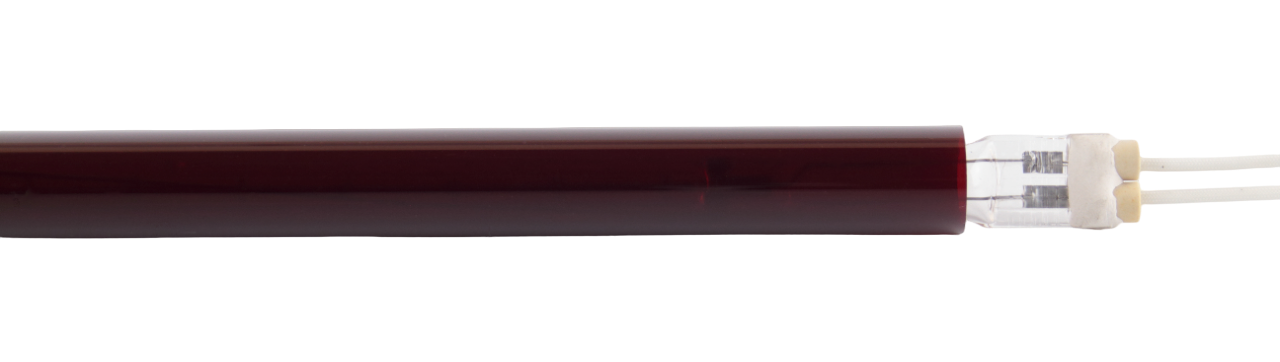

type: FQHS / Flat quartz infrared heaters with integrated reflector and one-sided lead end in multi-chamber system

The FQHS is an IR-heating element consisting of one or more primary radiators as IR-emitters, which together with an integrated reflector is located in a hermetically sealed outer quartz flat tube, the secondary chamber. Each chamber is filled with the atmosphere most suitable for it.

The FQHS is particularly suitable for heating a surface or a band. Due to the integrated reflector, the IR radiation is already directed and hits where it is needed for heating. The external melting must not exceed 350°C in operation under normal atmosphere. Use in a vacuum is also possible without any problems.

The switch-on time of the FQHS is approx. 1 second to reach the operating state.

The following are eligible

- Heating length up to 2 metres

- Heating power in combination with the supply voltage

- Emission maximum of the emitted IR radiation between 1,0 μm - 2,8 μm.

- Energy density in relation to the heating length up to 120W/cm.

We have a wide range of standard products. We will be happy to assist you in selecting the most suitable IR-heater for your heating task. Please do not hesitate to contact us.

The following table shows the standard types FQHS in different versions. They differ in the number of primary radiators, the radiation angle and the quartz cross-section.

Advantages

- Multi-chamber system hermetically sealed to the outside

- Directed IR radiation through integrated reflector

- High efficiency due to adjustment of the radiation direction

- Integrated reflector in its own protective gas medium

- Integrated reflector that cannot be negatively influenced from the outside

- Increased safety due to the multi-chamber system

- High durability

- Very short response time of approx. 1 second

- Infinitely variable 0-100%

- High efficiency through adjustment of the emission maximum

- Contactless heat transfer

- Can be used in vacuum

- Suitable for cleanroom

- Emission-free

- Resistant to acidic and basic substances (with the exception of hydrofluoric and phosphoric acid)

- Very low heat expansion

- High thermal shock resistance

Options

- Lead ends on both sides (Z)

- Switchable heating zones

- Customised assembly of the lead ends and contacts

- Angled outer fusion (90°)

- Ceramic end (K)

- Cable bend relief (T)

- Radiation filter in visible light range (F)

Type FQHS

Type FQHS-P

Type FQHS-2P

Type FQHS-3Y

Options

| Type | Description | Radiation | Radiation angle1 | Number of primary radiators | Flat quartz cross-section2 | Integrated reflector |

|---|---|---|---|---|---|---|

| FQHS | Standard | Surface radiator | 120° | 2 | 29x13 | x |

| FQHS-P | Parabol | Band radiator | 25° | 1 | 29x13 | x |

| FQHS-2P | Parabolic double | Band radiator intensive | 35° | 2 | 33x15 | x |

| FQHS-3Y | Parabolic triple | Intensive surface radiator | 120° | 3 | 33x15 | x |

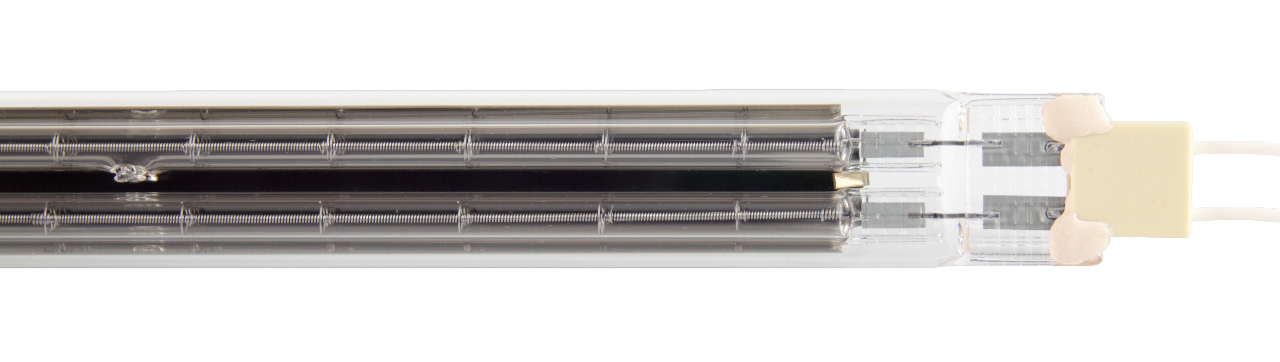

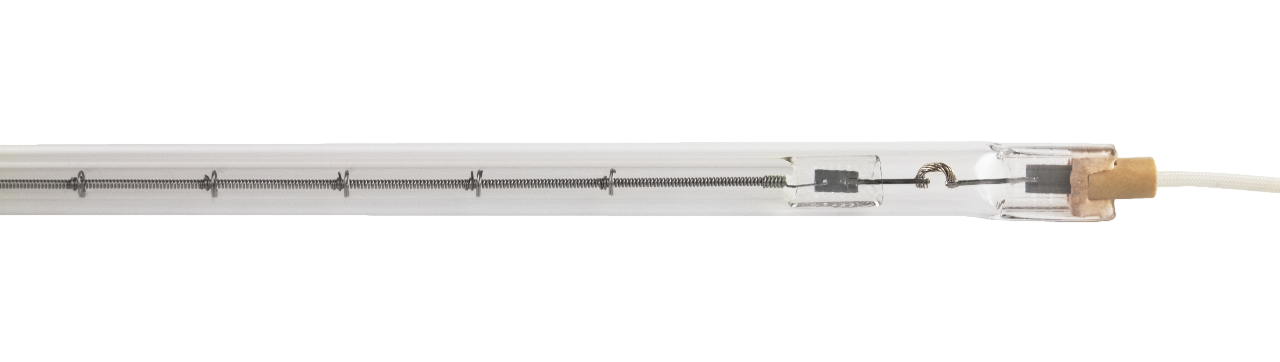

type: QHS / Quartz infrared emitters in multi-chamber system

The QHS is an IR-heating element consisting of one or more primary radiators as Infrared heating elements located in a hermetically sealed outer quartz round tube, the secondary chamber. Each chamber is filled with the atmosphere most suitable for it.

The QHS is mainly used for heating a room, such as a roller from the inside or in oven construction. In QHS version with a lead end on one side can also be used as an immersion heater in liquids. The QHS-R version with integrated reflector turns the standard QHS-S into an area radiator. If the IR radiation is to be directed elsewhere, it is recommended to use an external reflector. The external fusion must not exceed 350°C when operating in a normal atmosphere. Use in a vacuum is also possible without any problems.

The switch-on time of the QHS is approx. 1 second to reach the operating state.

The following are eligible

- Heating power in combination with the supply voltage

- Heating length up to 2 metres

- Emission maximum of the emitted IR radiation between 1,0 μm - 2,8 μm.

- Energiedichte bezogen auf die Heizlänge beträgt bis zu 150W/cm.

We have a wide range of standard products. We will be happy to assist you in selecting the most suitable IR radiant heater for your heating task. Please do not hesitate to contact us.

The following table shows the standard types QHS in different versions. They differ in the number of primary radiators, the radiation angle and the quartz tube cross-section.

Advantages

- Multi-chamber system hermetically sealed to the outside

- Directed IR radiation through integrated reflector (nur QHS-R)

- High efficiency due to adjustment of the radiation direction (nur QHS-R)

- Integrated reflector in its own protective gas medium (nur QHS-R)

- Integrated reflector that cannot be negatively influenced from the outside (nur QHS-R)

- Increased safety due to the multi-chamber system

- High durability

- Very short response time of approx. 1 second

- Infinitely variable 0-100%

- High efficiency through adjustment of the emission maximum

- Contactless heat transfer

- Can be used in vacuum

- Suitable for cleanroom

- Emission-free

- Resistant to acidic and basic substances (with the exception of hydrofluoric and phosphoric acid)

- Very low heat expansion

- High thermal shock resistance

Options

- Lead ends on both sides (Z)

- Switchable heating zones

- Customised assembly of the lead ends and contacts

- Angled outer fusion (90°)

- Ceramic end (K)

- Shrink tubing (S)

- Cable bend relief (T)

- Handle (H)

- Damping stop (A)

- Radiation filter in visible light range (F)

Type QHS

Type QHS-Z

Type QHS-2Z

Type QHS-R3

Options

| Type | Description | Radiation | Radiation angle | Number of primary radiators | Quartz cross-section2 | Lead ends |

|---|---|---|---|---|---|---|

| QHS | Standard | Radiant heater | 360° | 1 | ø13, ø15 | One-sided |

| QHS-Z | Switchable | Radiant heater intensive | 360° | 1 | ø13, ø15 | Both-sided |

| QHS-2Z | Switchable | Radiant heater intensive | 360° | 2 | ø20, ø25 | Both-sided |

| QHS-R3 | Integrated reflector | Surface radiator | 90° 1 | 1 | ø20, ø25 | One-sided |

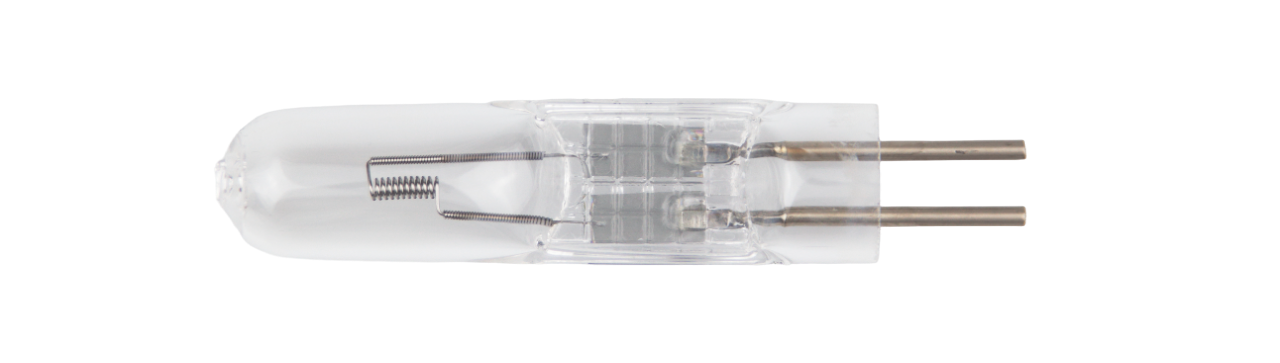

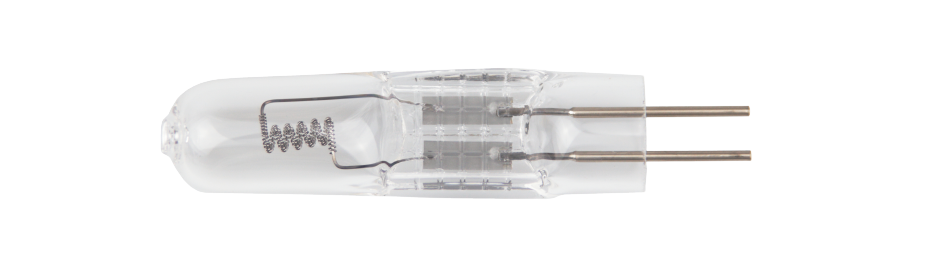

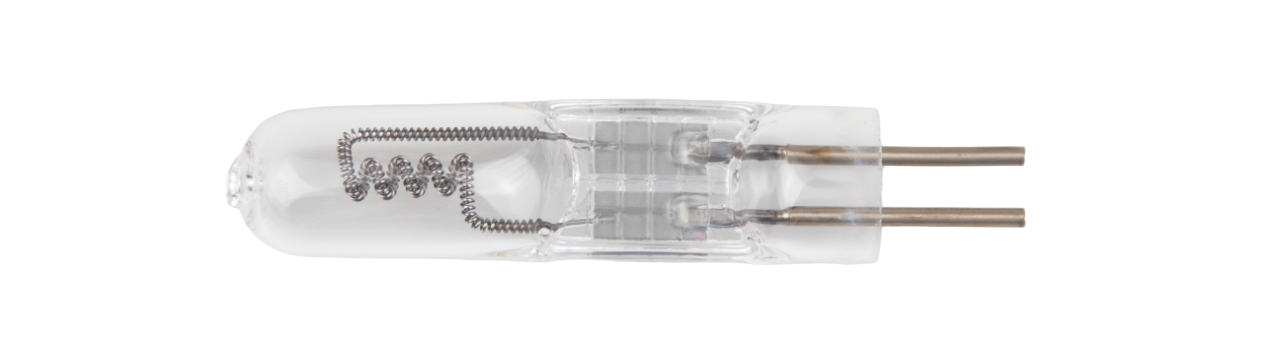

type: SHS / Pin-base radiant heater in single chamber system

The SHS consists of a heating coil made of high-temperature melting metal, the most suitable atmosphere for this and quartz glass as an envelope. This heating coil is heated by electrical energy and emits radiation in the infrared range with emission maxima of 0.8 μm - 2.8 μm. The efficiency of the conversion of electrical energy to IR radiation energy is up to 90% here.

The SHS is primarily to be used for heating a room. If the IR radiation is to be directed, it is recommended to use an external reflector. With the option of a gold reflector, which is located on the quartz glass, one obtains irradiation of a small area, such as is required for heating individual electronic components. The external melting must not exceed 350°C in operation under normal atmosphere.

The switch-on time of the SHS is approx. 1 second to reach the operating state.

The following are eligible

- Heating power in combination with the supply voltage von 0 – 30V

- Emission maximum of the emitted IR radiation between 0,8 μm - 2,8 μm.

- Energiedichte bezogen auf die Heizlänge beträgt bis zu 250W/cm.

We have a wide range of standard products. We will be happy to assist you in selecting the most suitable IR radiant heater for your heating task. Please do not hesitate to contact us.

The following table shows the standard type SHS.

Advantages

- Very short response time of approx. 1 second

- Infinitely variable 0-100%

- High efficiency through adjustment of the emission maximum

- Contactless heat transfer

- Emission-free

- Very low heat expansion

- High thermal shock resistance

Options

- gold reflector

Type SHS1

Type SHS2

Type SHS3

| Type | Description | Radiation | Radiation angle | Quartz cross-section1 | Lead end pin socket | Voltage and power2 |

|---|---|---|---|---|---|---|

| SHS1 | Standard | Radiant heater | 360° | Ø16 | One-sided | 12V-175W |

| SHS2 | Standard | Radiant heater | 360° | Ø16 | One-sided | 30V-200W |

| SHS3 | Standard | Radiant heater | 360° | Ø16 | One-sided | 30V-400W |

Industrial quartz infrared heaters for specialised heating solutions

Performance - Quality - Efficiency for heating and drying processes

Quartz infrared heaters - quality for generations

Since 1963, Quarz-Elektro-Bauelemente GmbH has been developing, producing and distributing self-manufactured, electrically operated infrared heaters, especially for industrial applications such as mechanical engineering, plant engineering and device manufacturing.

Efficiency, quality and know-how from individual parts to series production

With our product portfolio from individual parts to series production, we are gladly prove our motto: functionality and high durability resulting from principle, quality and know-how.

We can also solve your individual thermal engineering task

With decades of experience in manufacturing short-wave and medium-wave infrared heaters, our technical know-how in processing quartz glass in combination with high temperature resistant metals and high-vacuum technology we are the right partner for your heating process.