Accessories for IR emitters

With the accessories programme, our IR emitters can be optimally integrated into your processes.

In order to optimally fix, protect, direct IR radiation or otherwise usefully supplement our product range of Infrared heating elements, we offer you the following accessories:

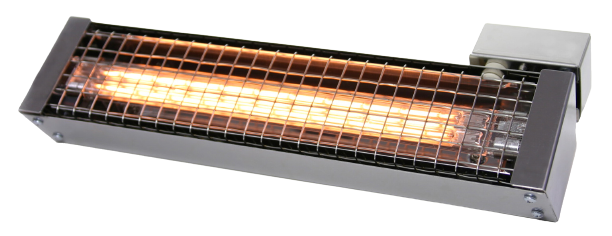

type: Protector / Protector Heater

The protective housing has been specifically designed for our IR-heater type FQHS. The integrated reflector is protected against environmental influences. The complete housing and all other materials used are made of stainless steel. For mounting the housing, there are two internal M8 threads at the back. The electrical connection is made via the thermally decoupled switch box, preferably with a silicone-insulated cable. The electrical protection must be provided externally.

Due to the thermal decoupling of the outer housing and the switch box, the protector heater can be operated without additional cooling.

Tyre manufacturers in particular appreciate the Protector heater for their rough industrial use.

We have a wide range of standard products. We will be pleased to assist you in selecting the most suitable IR heater for your heating task. Please do not hesitate to contact us.

The following table shows the standard types PH.

Advantages

- High durability

- Sturdy housing made of stainless steel

- Without forced cooling

- Easy installation

- Protection of the IR heater from external mechanical influences

- Very short response time of approx. 1 second

- High efficiency due to directed IR radiation

- Integrated reflector that cannot be negatively influenced from the outside

- Integrated reflector in its own protective gas medium

- Infinitely variable 0-100%

- Contactless heat transfer

- Gas emission-free

- Ideally suited for rough industrial use

Options

- Heating lengths according to customer requirements

- Heating capacity in connection with supply voltage according to customer requirements

Type Protector Heater

| Type | Description | Voltage and power | Radiation angle1 | Heating length2 | Housing3 |

|---|---|---|---|---|---|

| PH 220 | Standard | 230V-1250W | 120° | 220 | 320 x 76 x 48 |

| PH 330 | Standard | 230V-1250W | 120° | 330 | 430 x 76 x 48 |

| PH 460 | Standard | 230V-1250W | 120° | 460 | 560 x 76 x 48 |

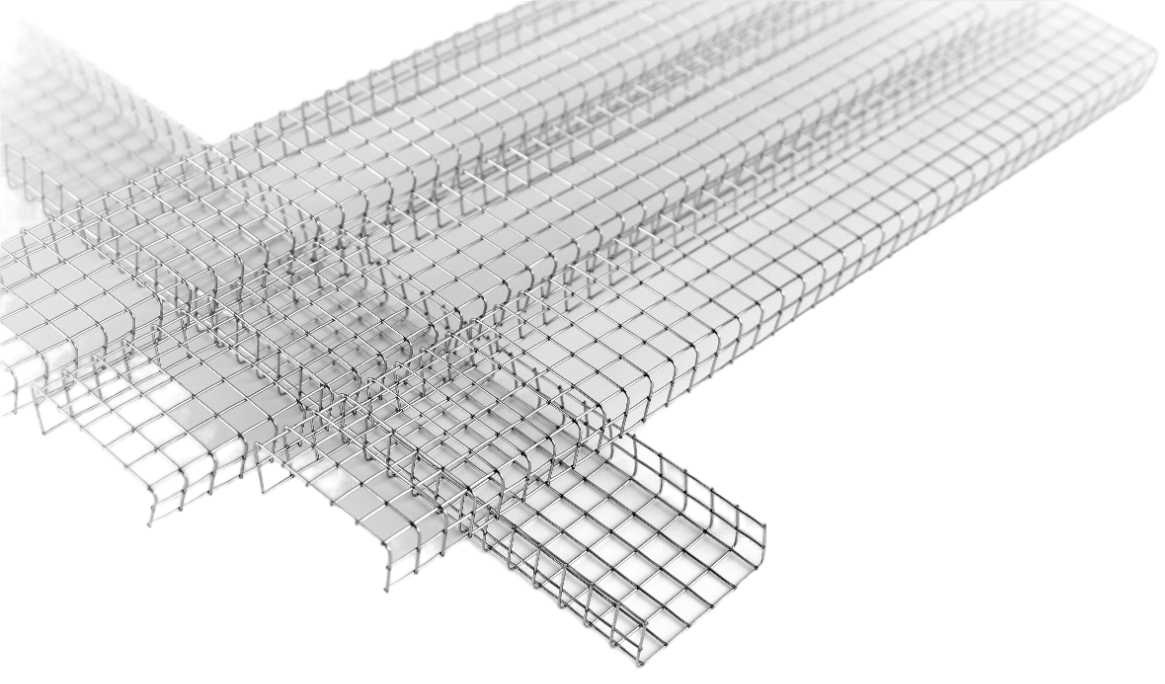

type: Protector grid / Protective grille

To protect the IR radiant heater from external mechanical influences, we recommend a protective grille. At the same time, this protective grille also serves as touch protection.

The grille material we use as standard is made of stainless steel with a mesh width of 10mm and a wire ø 1mm.

These geometric dimensions were chosen in consideration of the compromise of sufficient stability with as little IR radiation loss as possible.

We offer protective grilles according to your choice.

Advantages

- Protection for Infrared heating elements

- Touch protection

- Stainless material

- Lowest possible IR radiation loss

Options

- Cut to size according to customer requirement

- Curved according to customer requirements

Type Protective grille

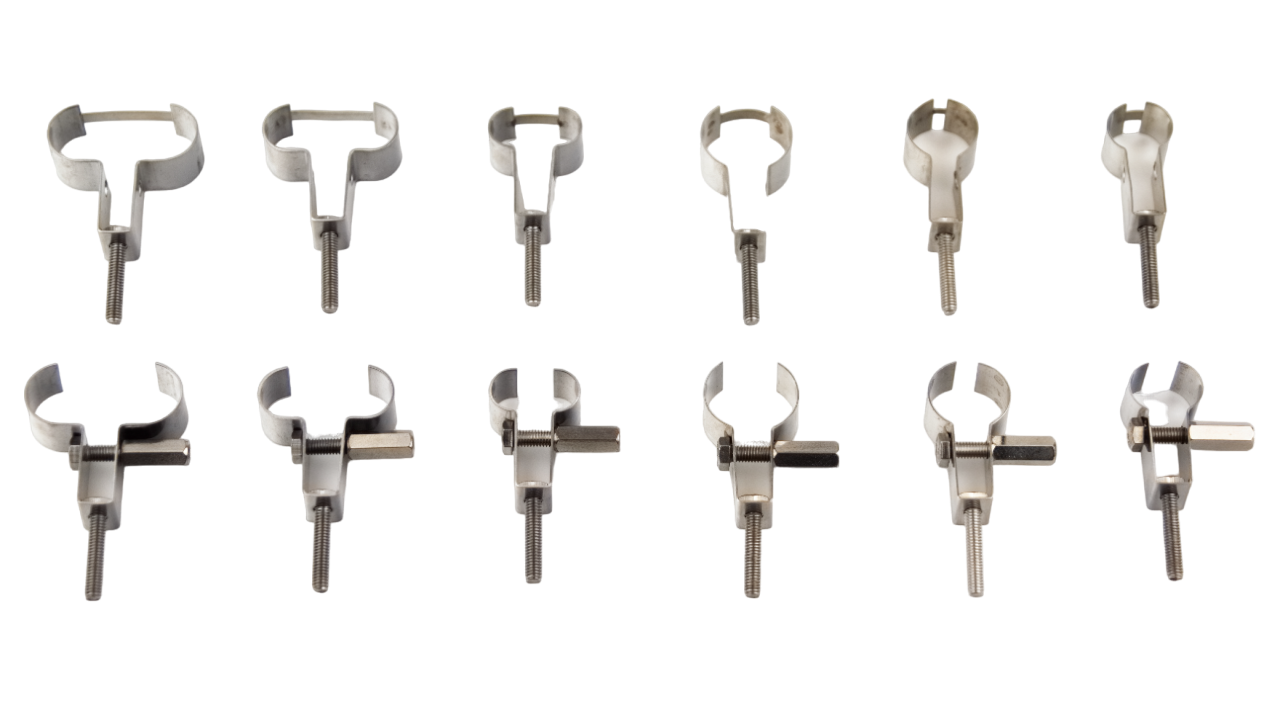

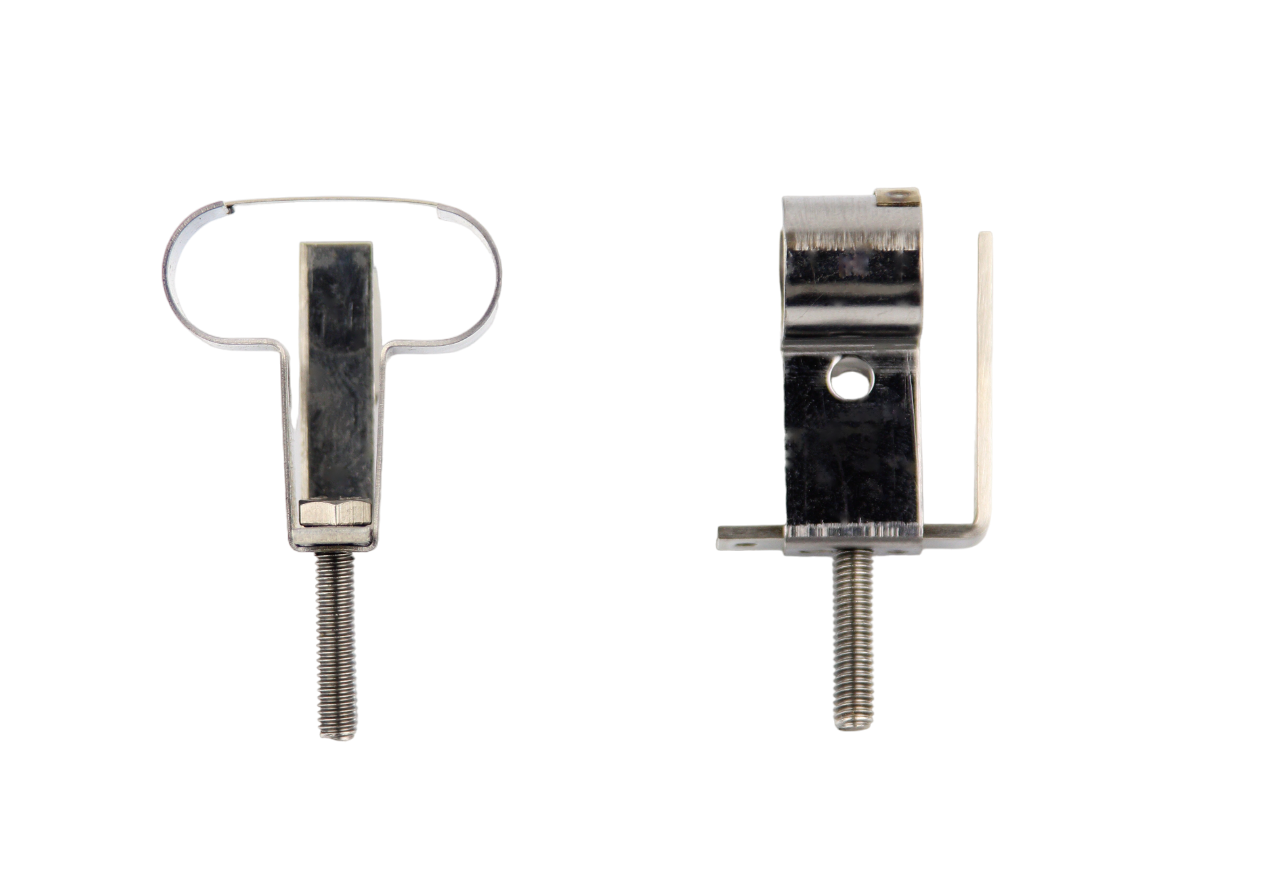

type: Clamps

In order to fix our IR heaters in the best possible way, we have the appropriate clamps for each quartz glass cross-section on offer.

Preferably, one retaining clip and one sliding clip are used per heater. With the retaining clip, the IR-heater is spring-loaded and locked in axial and radial direction. The sliding clamp only locks in the radial direction and allows axial movement. This axial movement occurs during thermal expansion of the base body to which the clamps are usually attached. The IR heater itself or the quartz glass has a very low thermal expansion with a coefficient of thermal expansion of 0.5 * 10 e-6/K.

The clamps are completely made of stainless steel.

In order to not disturb the radiation exit, the clamps should be placed outside the heating zone.

The self-retaining fixing screw simplifies the mounting of the clamps.

Easy mounting of the IR radiant heater is achieved by the self-retaining transverse screw in conjunction with the self-locking extra-long transverse nut SW6.

In order to always maintain exactly the same position during assembly, the sliding clamp can optionally be provided with a stop.

As a further option, we offer suitable ceramic bushings for thermal and additional electrical insulation.

Advantages

- Secure hold

- Spring-loaded locking

- Protection against glass breakage

- Robust

- Self-locking long nut

- Easy to mount

- Stainless steel material

Options

- Stop

- Ceramic version

Type Clamps overview

Options

type: Glass knitted mesh

For applications such as a flat heating window with radiation outlet on both sides, IR-heaters can also be held by means of friction to save space.

In order to not damage the heater, it must be ensured that the clamping device has no direct metallic contact with the quartz glass. A knitted glass mesh is suitable as an intermediate layer.

The knitted glass mesh guarantees a secure hold and prevents glass breakage on the IR radiant heater used. The thermal load capacity is up to 600°C.

We have knitted glass meshes from ø 4 mm - ø 8 mm in our range.

Advantages

- Secure hold

- Protection against glass breakage

- Application temperature up to 600°C

Type Glass knitted mesh

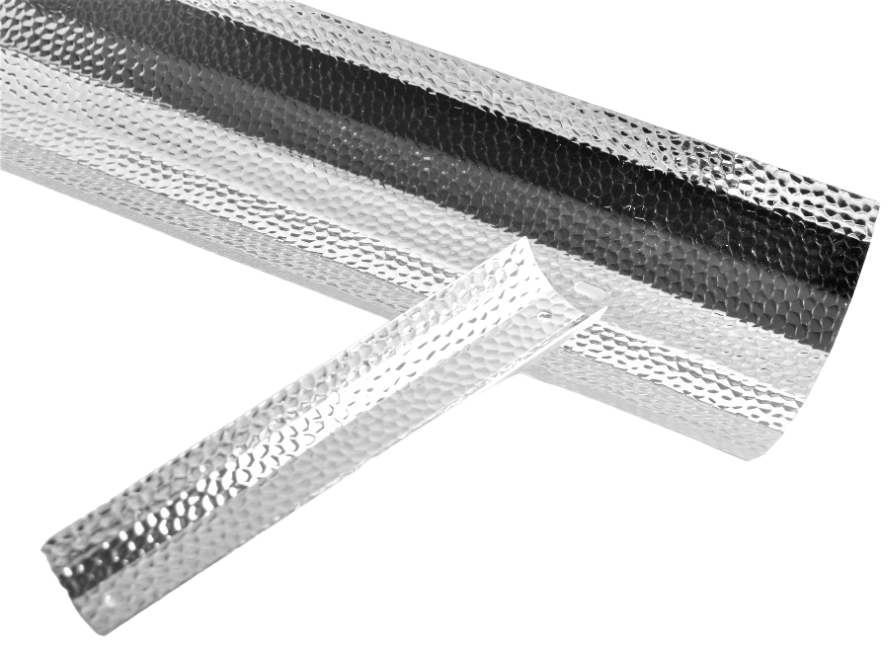

type: Reflectors / External reflectors, reflector plate

The non-directional IR radiation of a spatially radiating IR heater can be directed with an external reflector. This significantly increases the efficiency and thus the efficiency of the energy used. This requires the right reflector material and the right shape for the external reflector.

If required, the radiation angle of an IR panel heater with integrated reflector (type: FQHS) can also be reduced with an additional external reflector.

If, for example, the radiation from the spatially radiating Infrared heating elements (type: QHS or type: QS) is to be directed onto a surface or a band, this must be done with a suitable external reflector.

We offer you the reflector shaped according to your application needs with or without suitable mounting elements for the IR-heater. If you have any questions, please do not hesitate to contact us.

We offer reflector sheet metal blanks if you are planning and manufacturing an external reflector but lack suitable reflector material.

The reflector sheet we use is made of semi-hard aluminium, anodised and polished, with an efficiency in the infrared range of up to 95%, depending on the wavelength emitted by the IR heater and to be reflected.

Advantages

- High efficiency in the infrared range up to 95%.

- Stainless material

Options

- Custom made shape

- Custom made size

Type Reflectors

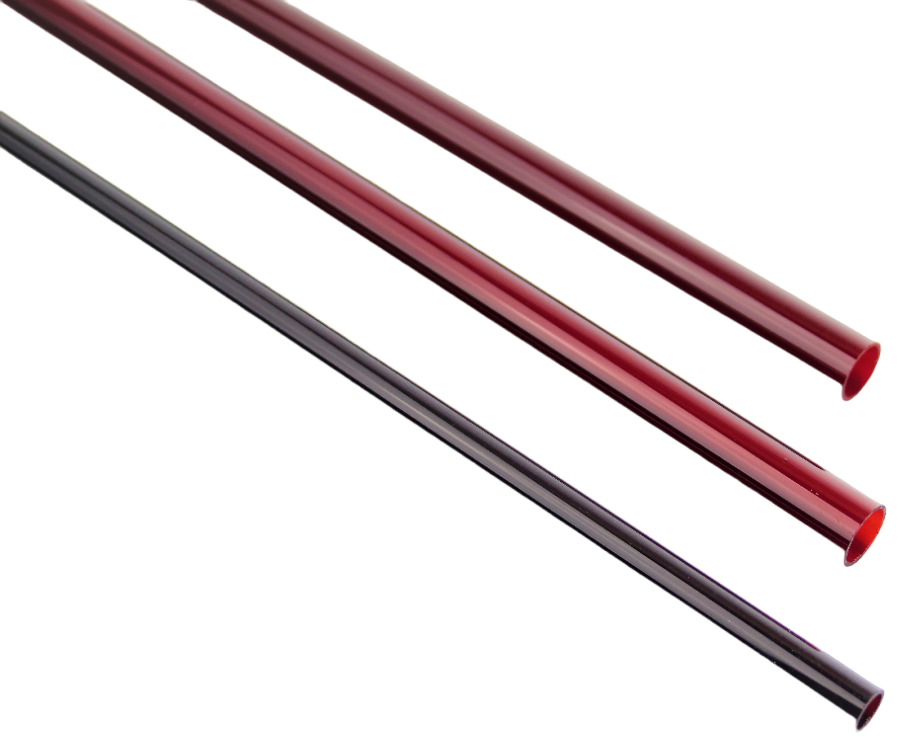

type: Filter tubes / Filter tubes / External filter tubes

Short-wave IR heaters also emit a small amount of visible light (up to approx. 10%) during operation due to the high heating coil temperature required. Depending on the application, this can be perceived as disturbing to the human eye.

If it is desired to reduce this emitted portion in the visible light range, we recommend the use of a suitable filter. The filter tube we use is made of doped quartz glass, with the known positive properties such as thermal shock resistance, low thermal expansion and acid resistance.

This external filter can simply be slid over the IR heater in the HH or QHS types. The outer fusion should protrude from the filter tube.

With the IR-heater types QHS or FQHS, the primary radiators can be manufactured as an option with doped quartz glass = filter tube instead of transparent quartz glass.

Advantages

- High transmission in the short-wave infrared range up to 92%

- Strong reduction of emitted visible light

- Resistant to acidic and basic substances (with the exception of hydrofluoric and phosphoric acid)

- Very low thermal expansion

- High thermal shock resistance

Options

- Custom made size

Type Filter tubes / External filter tubes

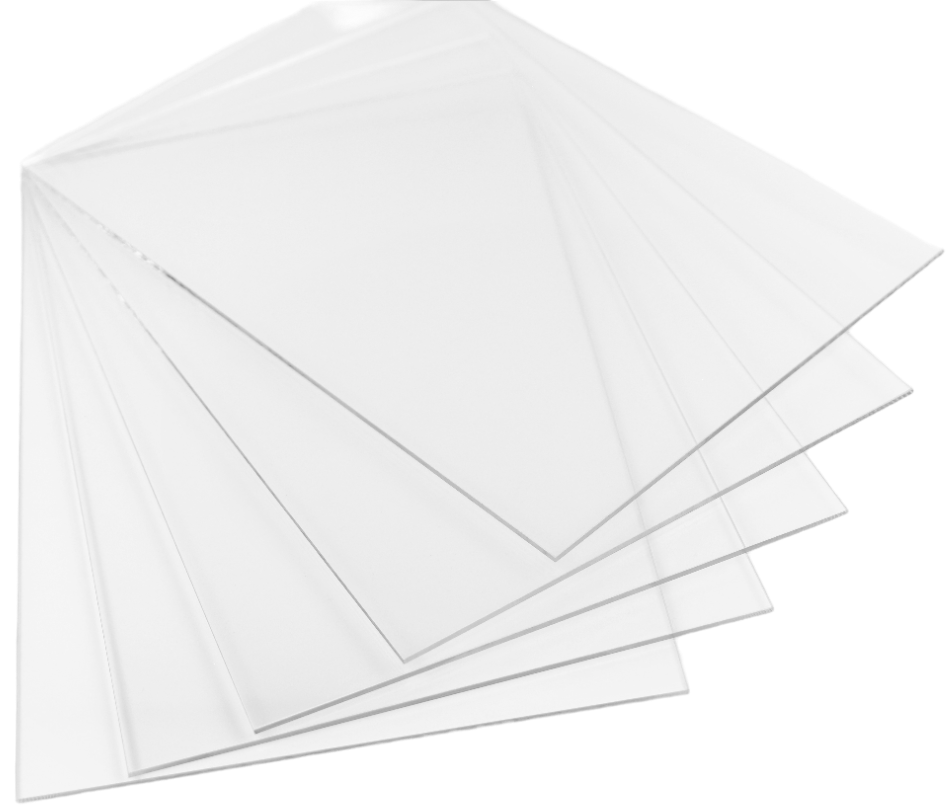

type: Protective screens

To protect IR heaters and/or external reflectors from dust, vapours or other undesirable influences in adverse environmental conditions, it is useful to use an IR radiation-transmitting protective screen.

Protective screens also provide additional safety, as required, for example, in IR applications involving people (cosmetics, medical technology).

Due to the long-term temperature resistance of the protective screens of 450°C and their good resistance to alternating heat, the protective screens are particularly suitable for use in combination with our short-wave Infrared heating elements.

Depending on the application, we have these IR-radiation permeable annealed protective screens on offer for you.

Advantages

- Long-term temperature resistance 450°C

- Protection for Infrared heating elements against external influences

- Protection for external reflector against external influences

- Additional safety

- Low thermal expansion

- High transmission in the short-wave infrared range

- Resistant to alternating heat

Options

- Custom made size

Type Protective screens